* Pilih kawasan atau lokasi yang bersesuaian dengan operasi (lihat post2 12 perkara yang perlu dipertimbangkan untuk memilih lokasi rumah lindungan)

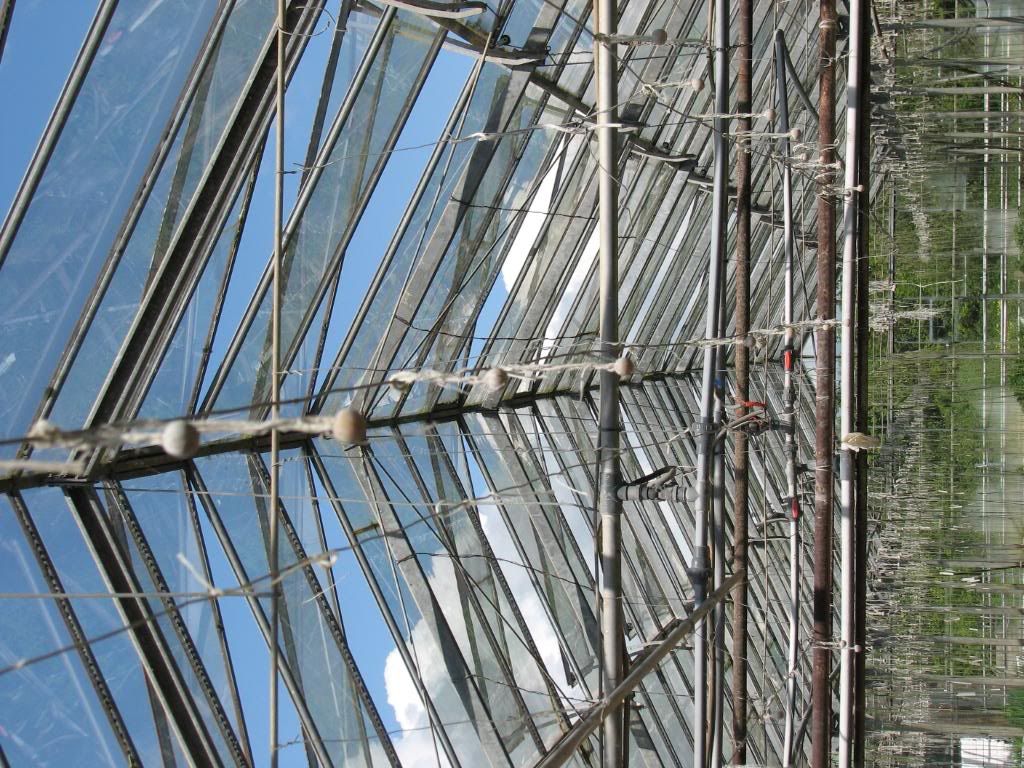

* Pilih struktur rumah lindungan yang bersesuaian (lihat post2 struktur & bahan komponen rumah lindungan)

* Pastikan kesemua peralatan adalah bersih, diservis dan berfungsi secara optimum.

* Untuk kesemua jenis tanaman, perkara-perkara berikut haruslah dipertimbangkan sebelum menanam:

- Kemasukan cahaya yang cukup - Pilihlah pelapik atap atau dinding (jika perlu) yang sesuai untuk membenarkan cahaya matahari menembusinya secara optimum. Namun begitu, jika merancang untuk penghasilan sepanjang tahun, gunakan jaring penapis sinaran cahaya (sunshade) pada musim panas terik.

- Sistem Penyejukan yang cukup - Samada penyejukan pasif (lubang/ruang udara) atau aktif (kipas) atau kedua-duanya sekali.

- Pembekalan gas Karbon Dioksida - Ini hanya selalu digunapakai di negara2 yang mengalami musim dingin.

- Pelapik/Pengalas tanah - Selalunya menggunakan bahan plastik putih atau berkilat (juga dipanggil Silvershine Weed Suppressor) digunakan. Ia memantulkan cahaya untuk meningkatkan kadar fotosintesis, memberikan perlindungan pada media tanaman dari patogen2 tanah dan mengawal pertumbuhan rumput./lalang.

- Mempermudahkan aktiviti2 pembersihan - Sampah2, daun2 kering dan air yang bertakung adalah habitat yang sesuai untuk serangga perosak & penyakit

- Sistem Pengairan/Irigasi Ini termasuklah 1) Alat pengatur masa (Timer) atau 'controller' untuk menetapkan jadual 'fertigasi'. 2) Bekas/takungan/tangki menyimpan air bersih atau larutan baja 3) Injektor 4) Tiub-tiub penyambung/penitis/pengitar larutan baja 5) Alat-alat penyukat pH, EC atau TDS 6) Dawai2 trelis -yang cukup kuat untuk menampung berat pokok untuk membuat ruang-ruang melintang bagi poko di dalam kawasan rumah lindungan.

Factors To Consider For The Greenhouse Preparation:

*Select a site for the greenhouse that is appropriate for the operation (see posts 12 Things To Consider When Selecting A Greenhouse Site).

*Select a greenhouse structure that is appropriate for the operation (see posts on Greenhouse Structure).

*Make sure all equipment is cleaned, serviced and working at optimum efficiency.

*For any crop, incl. tomatoes, the following items must be considered prior to planting:

- Good light transmission: Choose the proper greenhouse covering and structure. If year-around production is planned, shading must be used in Summer.

- Adequate cooling: Either passive (vents), active (fan and pad), or both. Heating is necessary in Winter: NATURAL GAS is the most economical way. (Other, more expensive, methods of heating: propane, oil, electric, solar.)

- Carbon dioxide generation: This is especially important for Winter mornings. The sun rises, but it’s cold. So if fans come on, it’s only for a short time. Plants begin to photosynthesize, using up the ambient carbon dioxide to the point where photosynthesis is effected and even reduced.. If photosynthesis is reduced, fruit set is reduced – and that’s $$!

- Ground cover: Usually white plastic or a white woven material is put down first. Reflects light back up into the crop increasing photosynthesis. Provides a barrier between the plants and pathogens in the soil. Helps to control weeds.

- Allows for ease of cleaning: CLEANLINESS IS PARAMOUNT! Trash, leaf litter, etc. is a perfect habitat for bugs/disease.

- Irrigation system: (see posts on Irrigation System for details and diagram) This inlcudes: 1)Timer/controller to regulate the “fertigation” (water + fertilizer) schedule. This will be hard-wired to solenoid valves that open for watering. 2) Reservoirs to contain the nutrient solution (full strength or concentrate). 3) Injectors (if concentrates are used) to dilute the nutrient solution. 4) Distribution tubing/emitters/drainage and/or recycling system. 5)Possibly integrated pH (acid/base) and EC (electrical conductivity) probes. 6) Overhead support wires: These need to be strong enough to support the crop and high enough (8-14 feet) to make use of the vertical space provided.