Bahan-bahan tang digunakan sebagai penutup/bumbung struktur rumah lindungan/rumah hijau boleh jadi tetap atau boleh diubah-ubah, 2 lapis atau selapis, licin atau beralun. Kebanyakan bahan pengilat yang dihasilkan sekarang ini menggunapakai bahan yang menghalang kesan buruk dari sinaran UV. Walaubagaimanapun, kesan bahan pengilat ini akan semakin haus dan diukur dari kadar jumlah tahun ia digunakan untuk membenarkan jumlah sinaran cahaya melepasinya. Antara bahan-bahan yang boleh digunakan termasuklah:

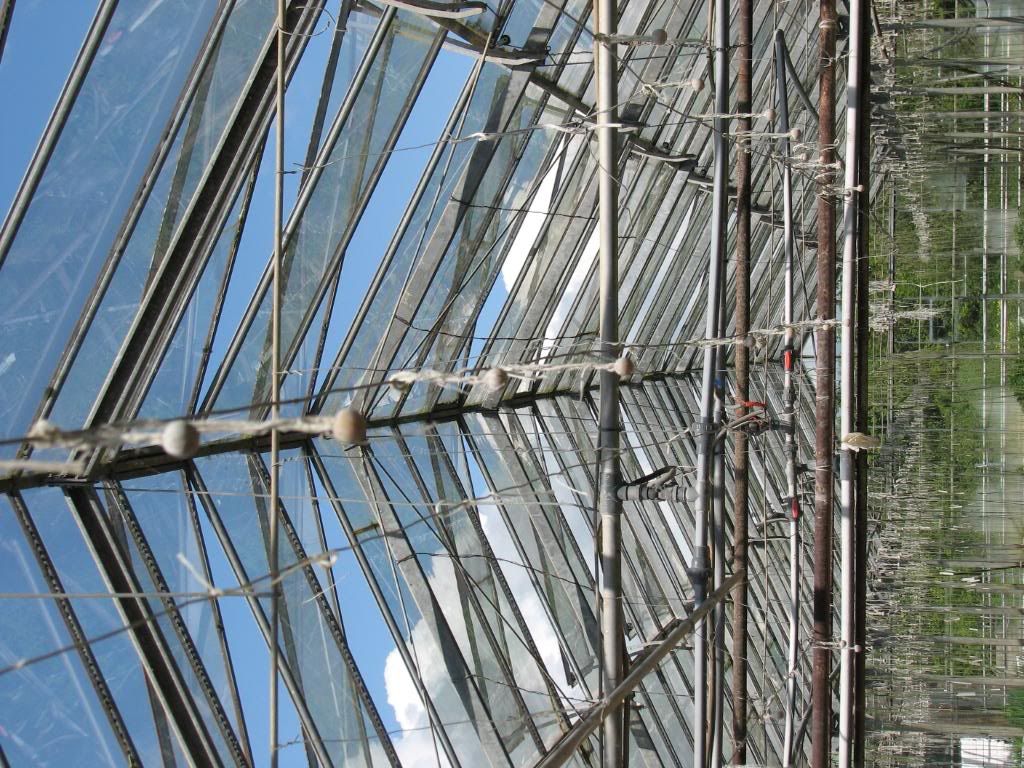

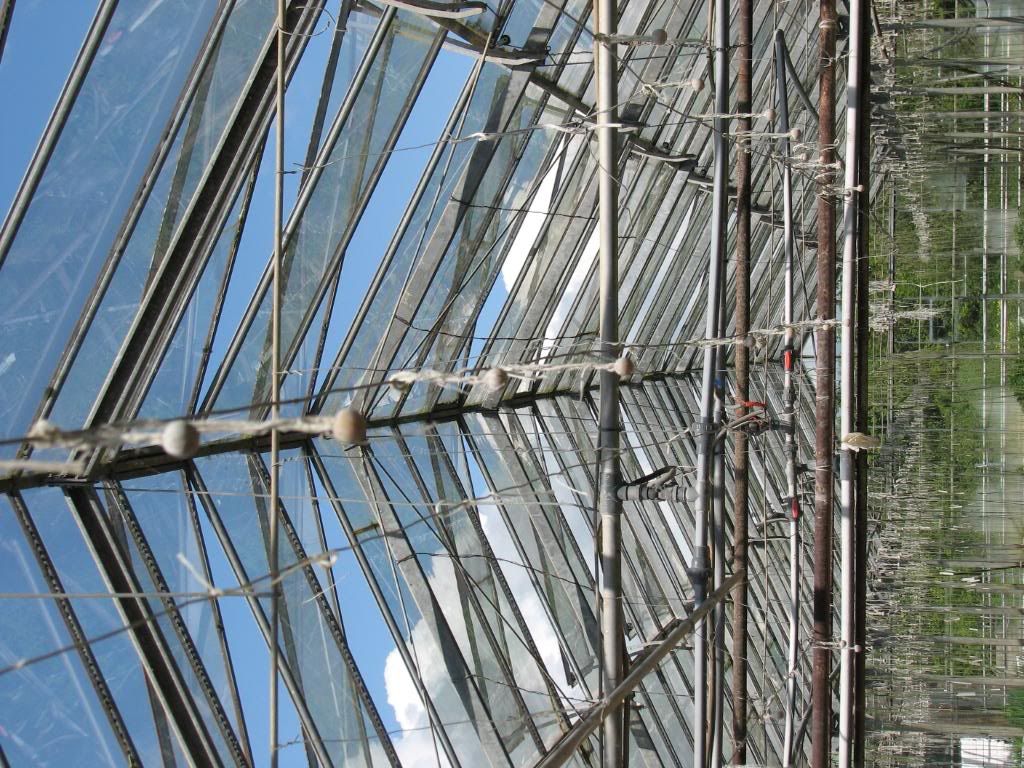

- Kaca - Ia telah lama digunakan (1 abad) di Eropah Utara. 'Rumah Kaca' memerlukan jumlah kayu yang cukup banyak untuk menampung berat kepingan-kepingan kaca. Ia lebih tahan lama (25 tahun) dan menyalurkan cahaya dengan lebih berkesan. Kadar PAR (Penembusan Cahaya) ialah 71% - 92%. Namun ia sangat mahal, berat dan mudah pecah. Kebanyakkan pengusaha sekarang ini lebih memilih bahan Polimer (plastik).

- Polyethylene: Ia dihasilkan di England pada 1938. Ia lebih fleksibel & ringan serta sering digunakan di rumah hijau yang berbentuk separuh bulat, melengkung dan berbentuk pintu gerbang. Kadar PAR ialah 85% - 87%. Namun begitu, jangka hayatnya hanya 2-4 tahun bergantung kepada lokasi & kualitinya.

- PVC: Satu lagi lapisan yang mudah diurus dan mempunyai kadar PAR yang sama dengan kaca. Ia sering digunakan di Jepun. Berbanding lapisan Polyethylene yang boleh dibentuk lebar, PVC lebih kecil dan tidak berapa sesuai untuk menutup rumah hijau.

- Gentian Kaca beralun (Corrugated fiberglass): Ini adalah bahan pelapis yang agak biasa bagi rumah lindungan. Kadar PAR 60 - 88%. Ia murah, kuat dan mudah diurus. Walaubagaimanapun, ia mudah dipengaruhi oleh sinar UV, habuk dan bahan cemar ( harus sering dibersihkan dan dicuci). lama kelamaan, ia akan menjadi kekuningandan mudah terbakar. Jangka hayat 7 - 15 tahun

- Acrylic: Ia ringan, mudah diurus & tahan pada sinar UV & cuaca. Nilai PAR ialah 83% (2 lapis) dan 93% (1 lapis). Jangka hayat 20 tahun atau lebih. Namun ia mudah tercalar, mudah mengembang dan lama-kelaan menjadi rapuh. Ia murah dan mudah terbakar.

- Polycarbornat: Ia ringan, murah dan tahan dengan tekanan/hentakan yang kuat. Nilai kadar PAR ialah 79% (2 lapis) & 87% (1 lapis). Penemuan terbaru telah menghasilkan bahan Polycarbornat yang lebih baik (contohnya 'Dynaglass' yang mempunyai nilai PAR yang menyamai atau lebih baik dari kaca). Ketahanan 5 - 10 tahun bergantung pada jenisnya. Ia mudah tercalar, kurang tahan pada perubahan cuaca tetapi tahan dari sinar UV. Namun, baru-baru ini, ia dapat diatasi dengan menyaluti bahagaian bahan ini dengan acrylic.

____________________________________________________________________

The materials used to cover greenhouse structures can be rigid or flexible, double-walled or single-walled, smooth or corrugated. Most “glazing” materials made today incorporate compounds that inhibit rapid degradation by ultraviolet (UV) radiation. However, all glazing material will age and they are therefore rated by the number of years they will maintain a certain level of light transmission capability. (Mica sheets were used in the 1st century A.D. as a glazing on Roman greenhouses. However, this material is no longer used, except perhaps as a demonstration of “ancient technology”.):

- Glass: This has been in use for at least a century in Northern Europe (Holland, England, etc.). Early glasshouses required significant wood and later metal structures to hold small but relatively heavy panes of glass. This reduced incoming light. Modern glasshouses have large panes of glass with reduced framing of stronger materials to increase light levels. Light transmission (PAR) is between 71 and 92 % depending on the type of glass and the estimated lifetime is 25 years or more. However, glass is inflexible, heavy, easily broken (unless tempered) and expensive and many growers are now opting for plastic materials.

- Polyethylene: First developed in England in 1938, this flexible, lightweight material is used extensively on hoop or arch style greenhouses because it is easy to work with and inexpensive. A single layer can be used or two layers can be applied with an air layer (maintained by a small fan) in between. This air layer adds insulation from heat and cold and adds structural strength with the double layer polyethylene houses being more stable in areas of high winds or typhoons. Light transmission (PAR) is around 85-87 %. Unfortunately, the estimated lifetime is only 2-4 years, depending on location and quality of the polyethylene.

- Polyvinyl chloride (PVC): Another flexible film that has light transmission qualities similar to glass. This material has been used extensively in Japan. While polyethylene sheets can be wide, PVC is narrow which is a disadvantage in covering greenhouses.

- Corrugated Fiberglass (also known as fiber reinforced polyester): This is a common greenhouse glazing. It is inexpensive, strong and easy to work with. Light transmission (PAR) is between 60 (double walled) and 88 %. However, it is susceptible to UV light, dust and pollution (hose down or wash periodically), yellows with age and is extremely flammable. The estimated lifetime is 7-15 years, depending on type of fiberglass . .

- Acrylic: This glazing material is lightweight, easy to work with and resistant to UV radiation and weather. Light transmission (PAR) is 83 % for double wall and 93 % for single wall. The estimated lifetime is 20 years or more. However, it is easily scratched, has a high expansion and contraction rate, becomes brittle with age, is expensive, and is flammable.

- Polycarbonate: This glazing material is lightweight, easy to work with and is resistant to high impacts. Typical light transmission (PAR) is 79 % for double wall and 87 % for single wall. However, recent advances have produced polycarbonates (e.g., “Dynaglas”, a single walled, corrugated material) with light transmission properties equal to or even exceeding glass. The estimated lifetime is 5-10 years, or more, depending on type.Previously, polycarbonate was known to scratch easily and have poor weatherability and UV resistance. However, recent advances in material properties have alleviated some of these earlier problems by coating the outer layer with acrylic.

No comments:

Post a Comment